I had the distinct pleasure and privilege of visiting Kohler at their campus in none other than: Kohler, Wisconsin at their invitation. To see and feel the heartbeat of this great American brand was a professional goal fulfilled.

I had the distinct pleasure and privilege of visiting Kohler at their campus in none other than: Kohler, Wisconsin at their invitation. To see and feel the heartbeat of this great American brand was a professional goal fulfilled.

I visited Kohler's headquarters at the end of October during a perfect fall weekend. It also happened to be the weekend of Kohler's Food and Wine Experience, a weekend filled with food and wine related events, seminars and workshops. I'm not overstating that this was such a great series of events that I'd love to go annually!

There are clearly several posts which I would like to share surrounding this weekend. First, you'll see some interesting pieces of Kohler's history. Second, I'll give you a look at the weekend's events which I know you'll also love. Third and probably fourth as well, you've just GOT TO SEE Kohler's fabulous Design Center! It will be worth the wait, I promise!

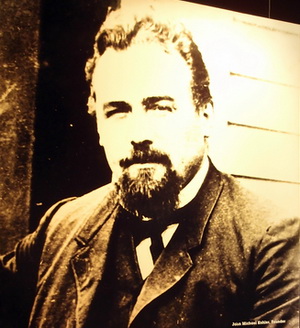

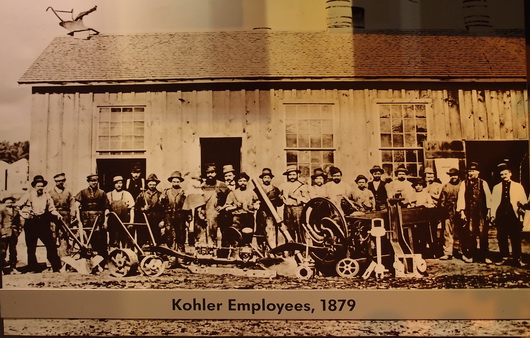

John Michael Kohler was 10 years old when his family came to the US from Austria and settled on a farm near St. Paul, Minnesota. At age 18, he moved to Chicago and became a traveling salesman for a wholesale grocery house and later sold furniture. His territory was the western seaboard of Lake Michigan. He formed a partnership in 1873 with Charles Silberzahn when they bought a foundry and machine shop from Kohler's father-in-law, Jacob Vollrath.

John Michael Kohler was 10 years old when his family came to the US from Austria and settled on a farm near St. Paul, Minnesota. At age 18, he moved to Chicago and became a traveling salesman for a wholesale grocery house and later sold furniture. His territory was the western seaboard of Lake Michigan. He formed a partnership in 1873 with Charles Silberzahn when they bought a foundry and machine shop from Kohler's father-in-law, Jacob Vollrath.

Kohler expanded the foundry to manufacture decorative iron pieces, cooking utensils and plumbing products. At the end of the 1800s a new factory was built in today's existing location, Kohler Village. Halfway through construction the plant burned down. Three months later John Michael Kohler died. Kohler's sons rebuilt the plant and renamed the busines John Michael Kohler Sons Co. in 1901. This is the overview.

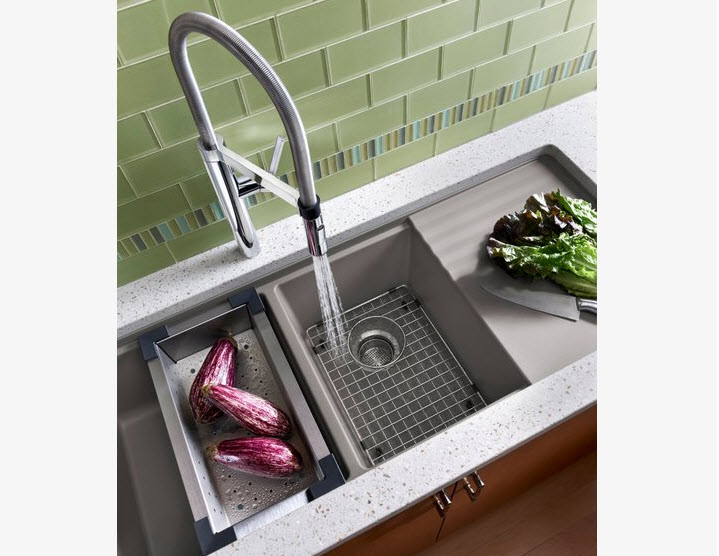

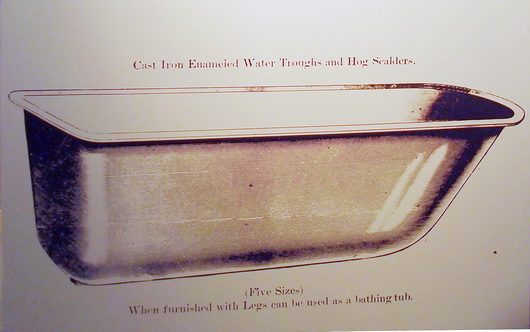

Below, plumbing begins...

In 1883, John Michael Kohler, and I quote, "enameled the inside of a horse trough/hog scalder, attached four cast iron legs, and sold it to a farmer as a bathtub. By 1891, the company expanded its line to include roll-rim bathtubs, washbowls, and drinking fountains. Acceptance of the Kohler bathtub and other enameled cast iron plumbing fixtures rapidly spread beyond the farm community. Cast iron products attained the reputation of being durable, sanitary, and 'superior as to beauty of design, excellence of finish, and quality of workmanship' "

Below, a bathroom from 1900

The mission of the company, from a 1900's catalog:

Over twenty years' experience in the manufacture and sale of Feed and Ensilage Cutters, Horse Powers, Feed Mills, and other Agricultural Implements has given us a thorough knowledge of the business. It has always been our aim during this time to manufacture the best goods that ingenuity and money can produce. There are grades of cheaper machines than ours on the market, we thoroughly believe, however, in the maxim, "That the best articles are the cheapest in the long run" and we have made it a rule not to see for how little money we could make an article, but how good we could make it for a moderate price. The fact that farmers who bought our machines twenty years ago are still using them, is conclusive proof of their excellence and a good endorsement. Our cutters and powers are all built on the most improved, scientific and practicable principles. We manufacture both the fly-wheel and the cylindar cutters.

We trust that the following pages will prove interesting and if in want of any machinery therein illustrated you will give them a fair, unprejudiced inspection and trial. Liberal discounts from lists allowed. Correspondence solicited. Respectfully, Kohler, Hayssen & Stehn Mfg. Co., Sheboygan, Wisconsin, USA.

As I put together this post, I truly am honored to have had the opportunity to learn about the history of a great American brand. I also walked through several large, old buildings (with state of the art machinery) that houses Kohlers factories and foundry. I saw the molten iron worked by expert craftspeople. I also saw highly skilled craftspeople work with great precision applying a finish. Impressive procedures, machinery and cleanliness are what I observed first hand. This was no small tour - it was 2 1/2 hours of walking and learning, led by a retired factory worker. It sure was memorable.

I hope you've enjoyed this first installment of my time spent at Kohler's headquarters. More to come, just wait!